Engineering, Procurement, and Construction (EPC):

EPC Contracts Explained: Meaning, Structure, and Role in Solar and Infrastructure Projects

In the world of infrastructure, power generation, and energy distribution, the term EPC has become synonymous with efficient project delivery. Whether you’re constructing a highway, a thermal power station, or a large-scale solar photovoltaic (PV) plant, the EPC model—Engineering, Procurement, and Construction—has emerged as a preferred approach for turning ambitious plans into operational assets.

This article answers essential questions such as:

-

What does EPC stand for?

-

What is an EPC company?

-

How do EPC contracts work for solar projects?

-

What is the difference between an EPC designer and an EPC developer?

Alongside these, we will explore the scope, stakeholder roles, quality assurance mechanisms, and project governance models that define EPC contracts.

What Does EPC Stand For?

EPC stands for Engineering, Procurement, and Construction. It is a form of contracting arrangement where a single contractor is entrusted with the complete responsibility of executing a project from design to commissioning.

Under this model:

-

Engineering includes surveys, design, and technical specifications.

-

Procurement involves sourcing and delivering all required materials and equipment.

-

Construction refers to physical installation, testing, commissioning, and handover.

This turnkey solution provides the client (also known as the project authority or owner) a ready-to-use project facility without managing multiple vendors or agencies.

What is an EPC Company?

An EPC company is a contractor or consortium that undertakes the entire project lifecycle—from concept to commissioning—under a single contract. These companies bring together expertise in:

-

Detailed engineering

-

Supply chain and logistics

-

Construction management

-

Project scheduling

-

Regulatory compliance

-

Testing and commissioning

EPC companies serve industries such as:

-

Power generation and transmission

-

Oil & gas

-

Infrastructure (roads, bridges, metro)

-

Renewable energy (especially solar and wind)

-

Water treatment and desalination

Examples of EPC Companies:

-

L&T (Larsen & Toubro) – Infrastructure and power sector

-

Tata Projects – Power and industrial EPC

-

Sterling & Wilson – Global solar EPC

-

Siemens Energy – Power EPC globally

How Do EPC Contracts Work for Solar Projects?

EPC contracts are particularly well-suited for utility-scale solar power plants, where the focus is on delivering a high-quality, operational solar facility within a defined timeline and budget.

Scope of Work in Solar EPC:

-

Engineering: Site analysis, solar resource assessment, panel layout design, inverter selection, SCADA integration, and grid interconnection planning.

-

Procurement: Purchase of solar modules, inverters, transformers, mounting structures, cables, and balance of systems (BoS).

-

Construction: Site development, civil works, panel installation, electrical connections, and grid synchronization.

-

Commissioning & Handover: Testing the entire plant, setting up monitoring systems, ensuring safety standards, and delivering performance guarantees.

Key Features:

-

Single Point of Responsibility: The EPC contractor ensures all components are compatible and integrated.

-

Performance Guarantees: Solar EPCs often include performance ratio (PR) or generation guarantees.

-

O&M Transition: Many solar EPCs offer an extended Operation and Maintenance (O&M) service for 5–25 years after handover.

Difference Between an EPC Designer and an EPC Developer

In the broader EPC landscape, especially in renewable energy, it’s essential to distinguish between an EPC designer and an EPC developer, as their roles differ significantly.

1. EPC Designer

-

Primarily focuses on technical engineering design.

-

Ensures structural, civil, electrical, and mechanical aspects are optimized and compliant.

-

Works closely with proof consultants and safety consultants.

-

May not be involved in procurement or construction directly.

-

Example: A design firm responsible for preparing the solar PV layout and grid-tie configuration.

2. EPC Developer

-

Responsible for the entire project lifecycle, often from land acquisition to commissioning.

-

Includes financing, permits, liaison with DISCOMs, and ownership transition.

-

Hires EPC contractors or manages in-house design and construction teams.

-

Often owns and operates the asset post-commissioning.

In short:

-

EPC Designer = Technical specialist

-

EPC Developer = Project owner/operator and integrator

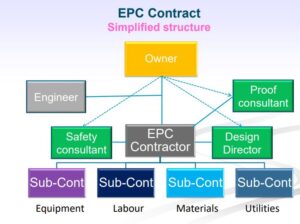

Structure of an EPC Contract

An EPC contract is usually signed between the project authority (owner) and the EPC contractor, with clearly defined deliverables, penalties, bonuses, and timelines.

Contractual Elements:

-

Scope of Work (SoW): Detailed list of activities and responsibilities.

-

Time for Completion: Milestones and final deadline.

-

Contract Price: Fixed or milestone-based payments.

-

Performance Guarantees: Efficiency, output, safety, and reliability parameters.

-

Liquidated Damages (LD): Penalties for delays or underperformance.

-

Advance Payment: Often 10–15% against bank guarantee.

-

Variation Clause: Mechanism for dealing with design or quantity changes.

Stakeholders in EPC Projects

Large EPC projects involve several key stakeholders and third-party experts:

1. Design Director

-

Appointed by the EPC contractor from a pre-approved panel.

-

Ensures completeness and compliance of all engineering work.

2. Safety Consultant

-

Independent of the EPC implementation team.

-

Ensures health, safety, and environment (HSE) compliance throughout design and construction phases.

3. Proof Consultant

-

Verifies and validates the design submitted by the EPC contractor.

-

Ensures structural and operational safety.

4. Authority’s Engineer (AE)

-

Appointed by the project authority.

-

Certifies work quality, inspects progress, and facilitates interim payments.

Quality Assurance in EPC Projects

High quality is a hallmark of successful EPC execution. Quality is defined as conformance to specified requirements, as per standards like MORTH, IS, IEEE, or IEC.

EPC Quality Framework:

-

Quality Assurance Plan (QAP): Submitted within 30 days of contract award.

-

Material Testing: Approved labs and third-party inspection.

-

Audit & Reporting: Daily, weekly, and monthly updates.

-

Non-Conformance Handling: Rework, replacement, or financial deductions.

-

Certification: QA sign-off needed for milestone payments.

Change of Scope and Subcontracting

Change of Scope

When project modifications are needed post-contract, a Change of Scope Notice is raised. It may include:

-

Additional components (e.g., fire systems, access roads)

-

Design modifications due to unforeseen conditions

-

Quantity variation beyond allowed thresholds

This leads to a Change Order and possible contract amendment.

Subcontracting & Assignment

-

Allowed only with prior written approval of the authority.

-

Critical activities usually cannot be subcontracted.

-

Unauthorized assignment is grounds for termination.

Challenges Faced in EPC Projects

Despite clear contractual structures, EPC projects often face hurdles:

Common Issues:

-

Environmental clearances and forest permits

-

Difficult terrain and extreme weather

-

Lack of skilled labor or local resistance

-

Frequent design revisions and site access delays

-

Coordination issues between consultants and contractors

-

Political or pandemic disruptions

Effective risk allocation, local engagement, and real-time monitoring are essential to overcoming these challenges.

Payment Terms and Financial Framework

Advance Payments

Typically 10–15% of the contract price is released as mobilization advance against a 110% bank guarantee.

Price Adjustment

Contracts may allow price variation (PV) based on standard indices (e.g., WPI, CPI) for long-duration projects.

Bonus & LDs

-

Bonus: For early completion or exceeding performance benchmarks.

-

Liquidated Damages (LDs): Charged per week/month of delay or performance shortfall.

Defect Liability and Post-Handover Period

Post-completion, the Defect Liability Period (DLP) ensures the contractor remains liable for:

-

Faulty workmanship

-

Malfunctioning components

-

Performance shortfalls

The duration varies (1–5 years), and performance security is retained or backed by a bank guarantee.

Conclusion: Why EPC Contracts Matter

EPC contracts offer a single-window solution for executing large, complex infrastructure projects with assured timelines, cost control, and quality benchmarks. In solar energy and public infrastructure, they bring together design expertise, global supply chains, and project execution under one umbrella.

By understanding the structure, roles, and challenges in EPC contracting, stakeholders—from developers and regulators to financiers and engineers—can ensure successful project outcomes that meet technical and commercial expectations.